Rapid gravity filter system

Customers, municipal authorities, and regulators demand safe drinking water. Failure to provide it can have serious consequences to the health of the local community, and the reputation of a water supplier can be damaged. Water utilities are facing increasingly stringent water treatment regulations and public health goals for known contaminants. In order to meet tougher regulations, it is imperative that water utilities optimize unit processes. Rapid gravity sand filter system is the heart of the water treatment processes.With more than 10 years of experience in the rapid gravity sand filter system, we support water plant to improve sand or dual media filter performance for superior results with lower filtrate turbidity, less backwash water consumption, less wastewater, and less operation and construction cost.

.png)

.jpg)

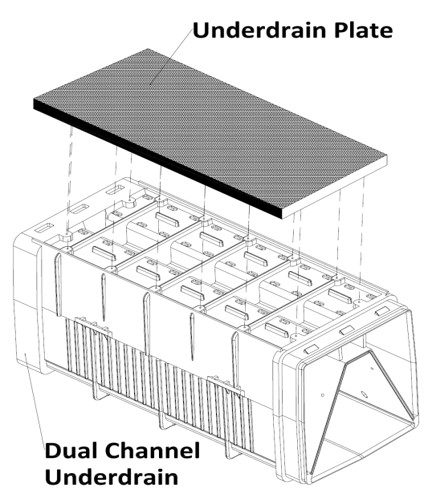

FEATURES OF DUAL LATERAL UNDERDRAIN FOR FILTER SYSTEM

- Provides superior distribution of backwash water and air.

- Closely Spaced Orifices, Eliminates Dead Spots.

- Provides Uniform Distribution of Filtration.

- Non Clogging Orifices.

- Corrosion Resistant Material.

- Smooth surfaces for reducing the potential for calcification.

- Media Retainer is factory installed on the top of Dual Lateral Underdrain.

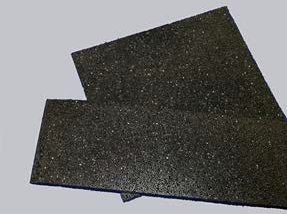

UNDERDRAIN PLATE

- Eliminates the need for support gravel

- Features: Lightweight, Strong, Proven flow distribution, and Compatible with water treatment chemicals.

- The plates are made from a non-toxic resin that meets all FDA specifications for food contact. The resin is also listed by NSF for use in potable water treatment systems. It offer an impact resistance surface that will not crack or deform. One inch thick plate weighs only 3lbs/ft2 but will withhold almost 700lbs/linear ft. This plates are made of a black ultra-violet resistant High Density Polymer resin. Because of strength characteristics, the plates can withstand rough handling without cracking, shattering, or deformation.

OPTIONS OF FILTRATION MODEL

- Constant Rate with Rate-of-Flow Control

- Constant Water Level filtration

- Constant Rate with Varying Water Levels

- Declining-Rate filtration

MEDIA BACKWASH CLEANING MODEL - Collapse-Pulsing

- Optimization of particle detachment by collapse-pulsing during air scour or concurrent backwash could be achieved. Three-phase systems utilizing simultaneous air scour and sub-fluidization water backwash provide the abrasion mechanism for aggressive particle detachment. Cleaning is significantly improved over particulate fluidization. The results of our experience indicate that flow combinations promoting Collapse-Pulsing behavior in a granular media filter provide the optimum condition for particle detachment by abrasion with less backwash water consumption, minimized media loss and less electricity cost.

AUTOMATIC CONTROL AND MONITORING SYSTEM

- Auto- or semi-Auto- backwash initiation based on run time, or filtrate turbidity, or water level of filter.

- Automatic control of backwash sequence and backwash flow rates.

- Monitoring of filtrate turbidity, flow rate, filter level, and backwash water/air flow rate.

- Operation through touch screen HMI and PLC.

COMPONENTS

A number of interrelated components are involved in the overall design of rapid gravity sand filter system:- Regulatory requirements

- Pretreatment systems

- Filter media

- Filtration rates

- Depth of the filter box

- Mode of operational control

- Filter washing system

- Filter arrangements

- Underdrain system

- Filter performance monitoring

- Auxiliaries

WE SUPPLY

- Material and Equipment, Design calculations, Engineering drawing, Presentations, and Proposals for a new design rapid gravity filter as well as a retrofitting one.

- Excellent customer support & After-sales service.

- Supply of basic and detail engineering on request.

.png)